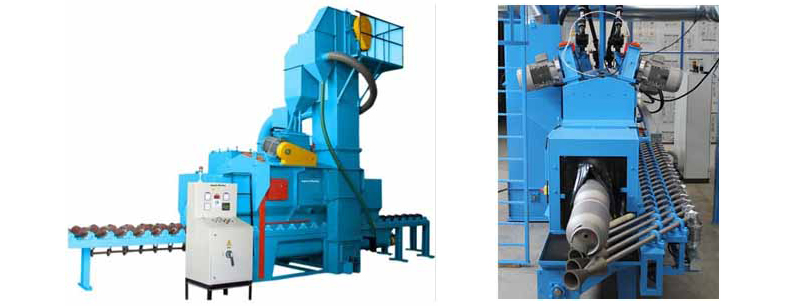

AMST offers corrosion protection solution for LPG cylinders. These cylinders are always stored and used in the area of highly corrosive climatic conditions. For safety of the cylinders shell, the outer surface is duly blasted and zinc spray coated to prevent against corrosion. AMST offers automatic airless type shot blasting machine and semi-automatic / fully automatic zinc spray metallizing system. The conveyor system and number of blasting / metallizing stations are designed to meet customer’s production requirements.

AMST offers automatic diabolo type airless shot blasting machine for LPG cylinders. Fresh cylinder can be loaded on the inlet of diabolo conveyor and passed through the blasting chamber where two blast wheels propels shots on the surface of LPG cylinder thereby shot blast external surface. Blasted LPG cylinders comes out of the blasting chamber on exit conveyor for being lifted by the operator. Dust generated during blasting process is sucked & collected in the dry filter cartridge type dust collector.

AMST offers semi-automatic / automatic zinc spray coating / metallizing system for LPG cylinders. Fresh cylinder can be loaded on the inlet of roller conveyor and passed through the metallizing booth where operator performs arc spray coating operation / automatic arc spray system coats LPG cylinder thereby metallize external surface of LPG cylinder with pure zinc metal. Dust and over spray zinc particles generated during metallizing process is sucked & collected in the twin cyclone dust collector and dry filter cartridge type dust collector