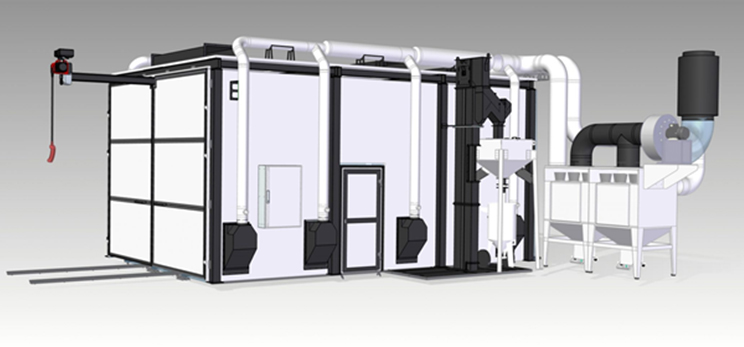

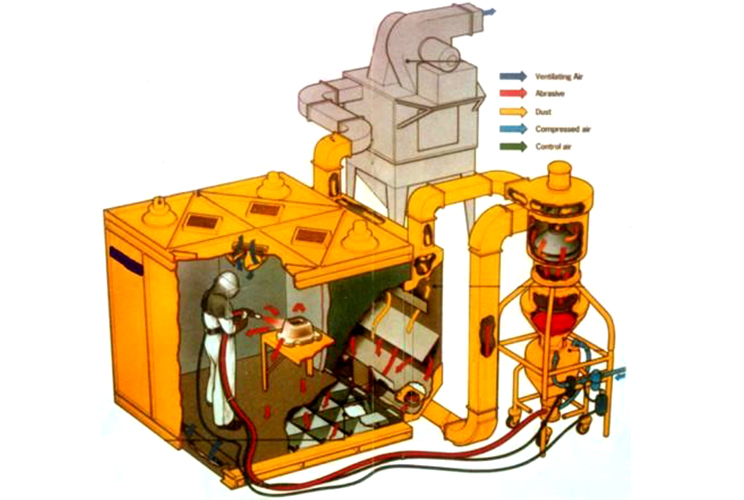

AMST offers grit blast room to offer an enclosed process of grit blasting for big size of jobs which cannot be blasted in small cabinet or in open atmosphere. AMST blast rooms are designed to meet customer’s requirement for effective & efficient blasting operation and operator’s comfort with suitable safety wears. AMST blast rooms are designed accordance to ISO & CE requirements. The blast rooms are equivalent to other OEM brands like Clemco, Rosler, Wheelabrator, Guyson. Etc.

Blast room includes a blasting enclosure duly rubber lined from inside, grit recovery system, mechanical type or vacuum recovery type, portable blasting machine, dust collector, exhaust fan and job handling unit like trolley , overhead conveyor, etc.

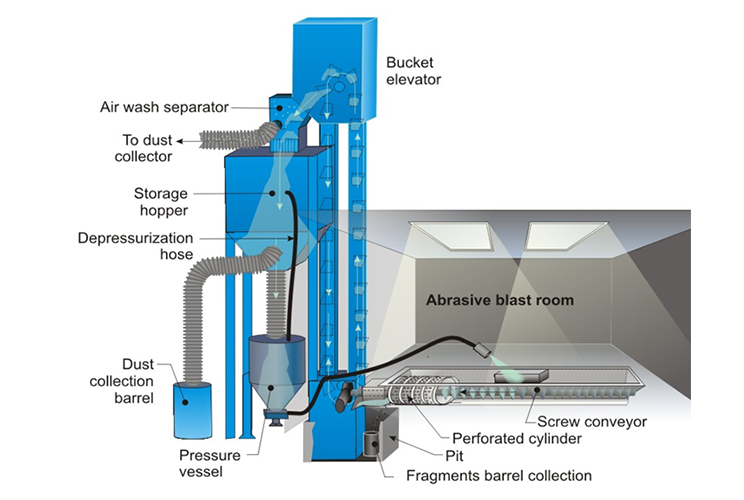

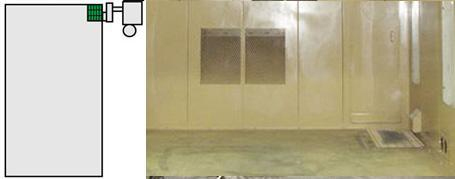

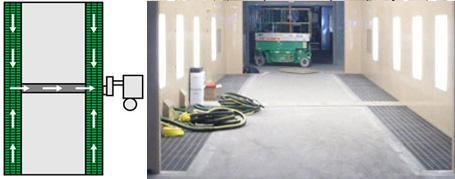

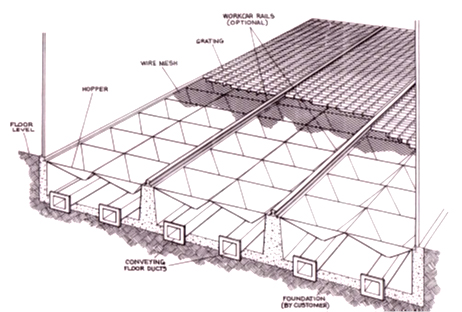

AMST Offers mechanical type grit recovery / recycling system inside the blast room as per customers requirement. The recovery is screw conveyor & bucket elevator type with rotary screen separator for grit recycling. Following are the floor designs for the recovery unit:-

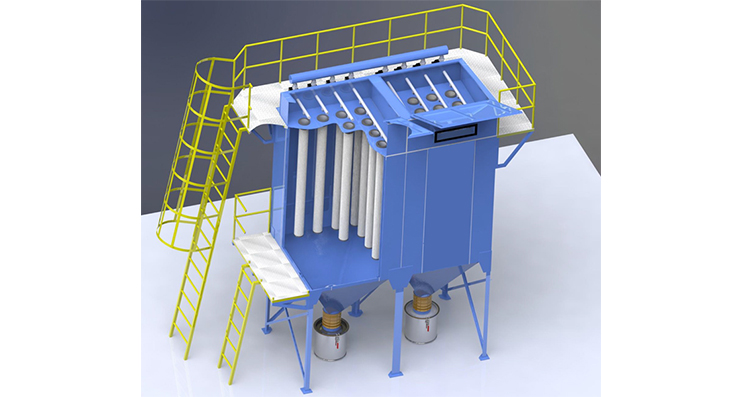

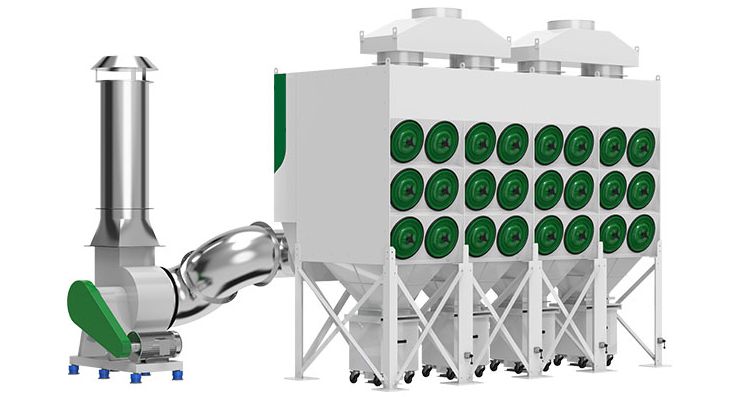

AMST offers dust collector for blasting room for the suction of suspended dust partcicles during blasting operation and to trap the dust particles in the dust collector thereby allowing clean air to discharge into the atmosphere.

AMST offers various types of dust collectors:-

AMST offers material handling system for carrying heavy job in the blast room. The job can be placed on the trolley / work car or can be hanged on the overhead type mono-rail hoist conveyor, as per buyer’s choice and application requirement.