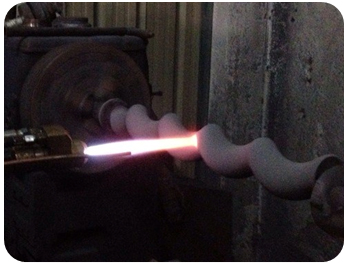

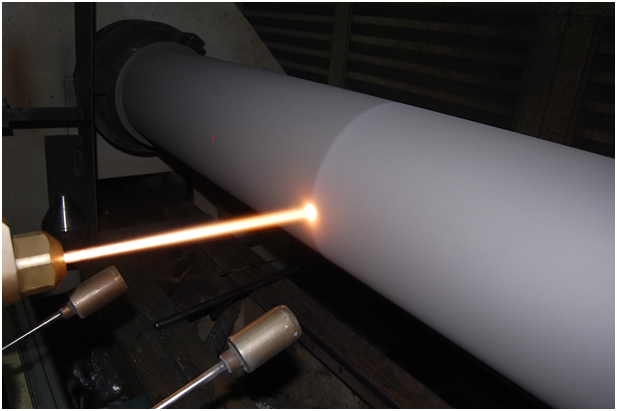

AMST offers gas fuel HVOF spray coating system “MACHJET-I” to spray coating powders like all powders from Tungsten carbide family, metallic, self-fluxing, etc to offer high wear, erosion, cavitations, etc resistant coating on the surface. Offered MACHJET-I HVOF system is designed to work with Fuel (LPG/Propane), Oxygen and compressed air. The offered system is mostly use for manual HVOF coating application and thus considered as entry level of HVOF coating requirements for any job shop.

The offered MACHJET-I HVOF system consists of MACHJET-2700 HVOF gun, Rotameter type control panel, MJ-3100, Volumetric feed powder feeder MFD-3500 which is similar to Tafa Praxair’s 1264 , Gas control unit, air control unit and portable trolley. The offered HVOF gun MACHJET-2700 is equivalent to Oerlikon Metco Diamondjet Type DJ-2700 HVOF spray gun.

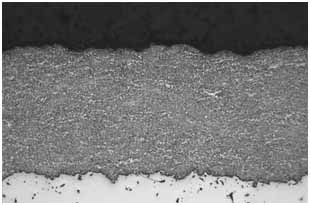

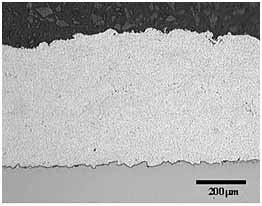

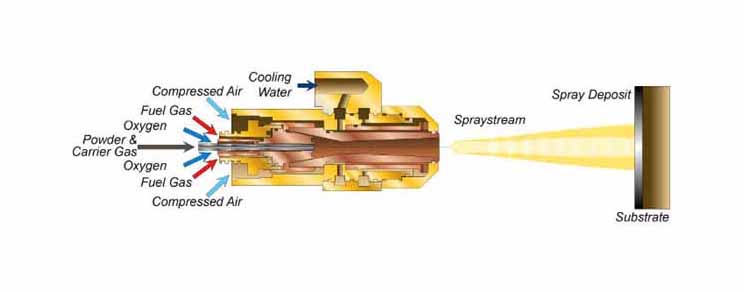

The model AMST HVOF system MACHJET-I sprays carbide powders melts in the HVOF gun MACHJET-2700 due to combustion takes places in the gun by Oxygen & LPG/Propane fuel with compressed air as atomising source for spraying molten material on the substrate thereby generating high quality & dense coating on the surface.

| MACHJET-2700 HVOF GUN | |

|---|---|

| POWDER TYPE | : Carbides, Metallic : self-fluxing & other Alloyed Powders |

| FUEL GAS | : LPG/Propane (Std) : Propylene (Opt) |

| TYPE OF GUN COOLING | : Air Cooled |

| POWDER FEED | : Axially in the nozzle |

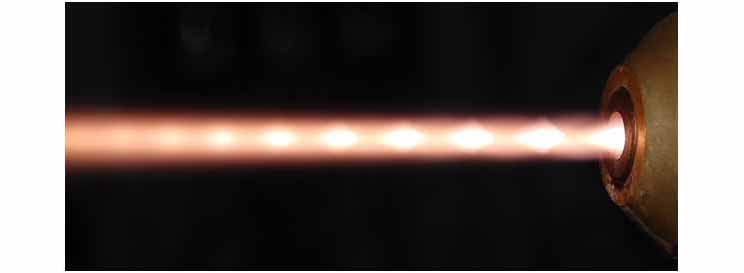

| PARTICLE SPEED | : Greater than 330m/s |

| WEIGHT OF THE GUN | : 1.6 Kgs Approx |

| GASES REQUIRED | : Fuel, Oxygen & Air |

| CONTROL PANEL MJ-3100 | |

|---|---|

| MEASUREMENT | : Rotameter Type |

| NUMBER OF GASES | : Fuel, Oxygen & Air |

| TYPE OF MOUNTING | : On the Trolley (Std) On the wall (Opt) |

| SAFETY FEATURE | : Flashback Arrestor On Oxygen Supply |

| INTERLOCK FEATURE | : With Compressed air |

| GAS FLOW ADJUSTMENT | : By Knob |

| ADDITIONAL FEATURE | : Hybrid selection Emergency stop 1Ø/220V/50/60 Hz |

| POWDER FEEDER PFD-3500 | |

|---|---|

| TYPE OF FEED | : Volumetric feed : Fine & Coarse Disk |

| CARRIER GAS | : Nitrogen / Argon |

| CANISTER CAPACITY | : 3500 c.c Volumetric |

| FEED RATE | : Variable with disk |

| RPM CONTROL | : By Potentiometer |

| MEASUREMENT | : Rotameter Type |

| ELECTRIC CONNECTION | : 1Ø/220V/50/60Hz |

| PORTABLE STAND | |

|---|---|

| A Portable stand is offered for mounting control panel, gun stand, powder feeder, LPG vaporizer, Controller and storing of hoses. | |

| WATER COOLED JACKET | |

|---|---|

| Water cool jacket offered for MACHJET-2700 HVOF gun for generating dense coating. Water supply is connected from the chiller to the gun to cool the hybrid hardware on the gun. | |

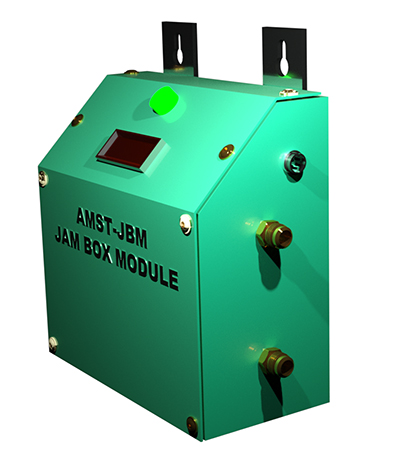

| WATER JAM MODULE AMST-JBM | |

|---|---|

| Water jam module for monitoring return hot water from the water cool jacket of the HVOF gun. Jam module has a temperature sensor to measure the return water temperature and also displays the water temperature on a digital display provdied on the jam module | |

| LPG VAPORIZER | |

|---|---|

| AMST offers a LPG vaporizer to vaporize the liuid content in the LPG gas so that liquid particles converts to gaseous state and thus allows smooth ignition of the HVOF gun. The gaseous state of the LPG fuel offers high quality melting of the coating powders due to proper combustion of the fuel. | |

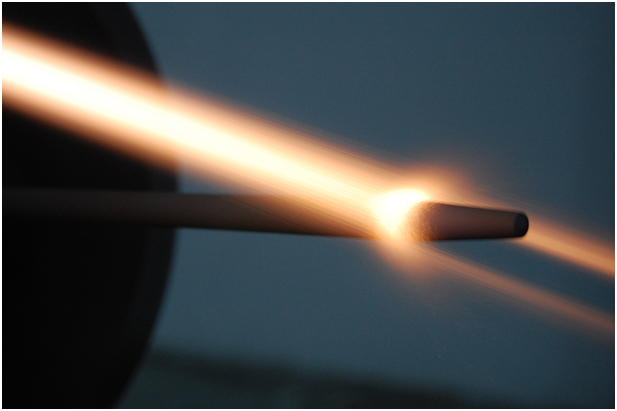

The HVOF spray process efficiently combusts oxygen and a gaseous fuel to produce high kinetic energy with controlled heat input. The coating material, in powder form, is introduced into the flame and uniformly heated by the hot gas stream to a molten or semi-molten condition. The flame and powder are accelerated by a nozzle (air cap) to produce supersonic gas and particle velocities, which propel the powder particles toward the substrate to be coated.